Porous chuck

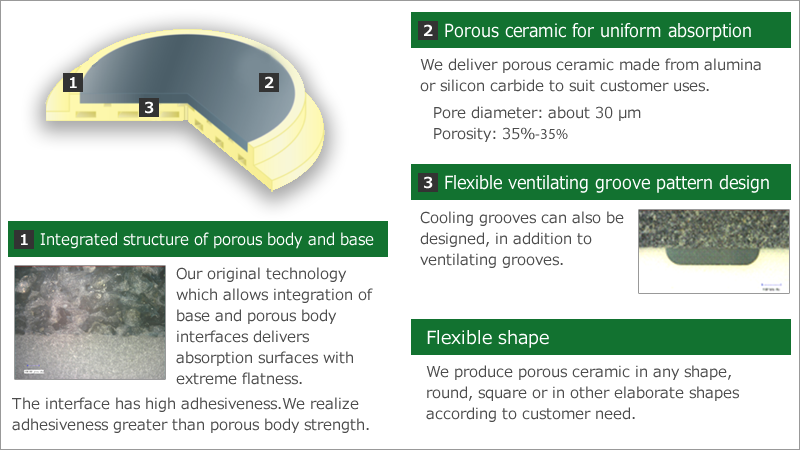

Our original manufacturing method enhances adhesiveness between porous sections and base sections to achieve sufficient flatness even at boundary sections.

We can provide highly productive and reliable wafer thinning processing and manufacturing requiring whole surface absorption of large sized substrates.

We offer a wide selection of porous bodies with using different materials and pore sizes to cater to user needs.

We can also provide cooling hollow grooves in ceramic bases.

Features/Usage

Features

Usage

- Fixation tools for wafer thinning process (grinder, polisher, CMP)

- Fixation tools for several measuring and inspection devices

- Fixation tools for processing film sheets and metal substrates

*We can provide surface coating according to purpose (for mold releasing, electrical conductivity, etc.)

Characteristics Chart

| Product number | Density g/cm3 | Coefficient of elasticity GPa | Bending strength MPa | Coefficient of thermal expansion ×10-6/K | Coefficient of thermal conductivity W/m・K | Electrical resistance Ω・cm | |

|---|---|---|---|---|---|---|---|

| Alumina | A995 | 3.9 | 380 | 450 | 7.3 | 30 | 30 |

Alumina porous | - | 2.5 | 55 | 50 | 7.4 | - | 30 |

| Silicon carbide | Standard product | 3.1 | 410 | 500 | 4.6 | 170 | 170 |

| Silicon carbide porous | - | 2.1 | 55 | 50 | 4.7 | - | 26 |

Our Technologies

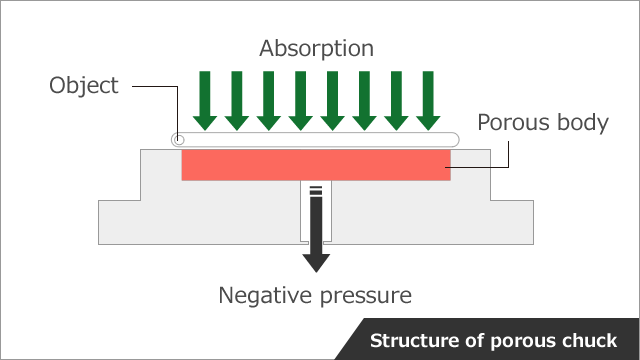

◆Mechanism of absorption and fixation

An object is absorbed and fixed to an intended place using negative pressure applied to a porous body.

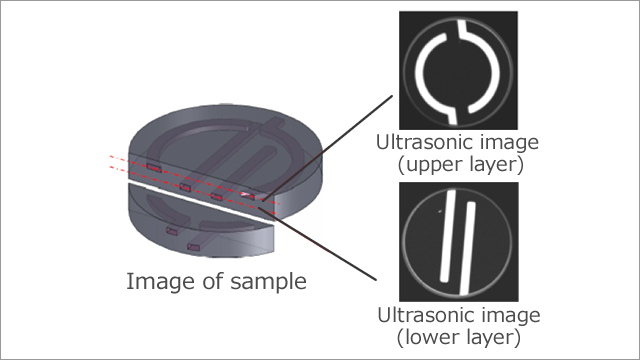

◆Hollow groove integrated structure

Hollow grooves can be formed inside porous ceramic without leak risk.